Warning and disclaimer:

If you don't have any basic electronics knowledge, please don't try this one. The author takes no responsibility for any damages caused as a result of this tutorial. Try this one at your own risk.

I am going to use a STC89C52RC microcontroller, a HC-06 UART interface Bluetooth module and a L298N motor driver module to biuld a Bluetooth remote control toy car. The toy car is controlled by Bluetooth Remote Toy, which is an android based application developed by me and can be downloaded form Google play store, so you can remotely control toy car via Bluetooth by your android phone. The toy car commands are as follows.

Every command consists one byte. If you stop a certain action, an OR operation will be performed between that action command and the Stop/Off command. For example,

- 0x01000100(Forward) | 0x00100000(Stop) = 0x01100100, which will be sent to the toy car and make it stop forward.

- 0x01001000(Front light) | 0x00100000(Off) = 0x01101000, which will be sent to the toy car and make it turn off the front light.

The red, green and blue buttons are reserved for those who want to do extra actions.

| Control Function | 1-byte Command |

|---|---|

| Red button | 0x01000001 |

| Green button | 0x01000010 |

| Blue button | 0x01000011 |

| Forward | 0x01000100 |

| Backward | 0x01000101 |

| Right | 0x01000110 |

| Left | 0x01000111 |

| Front light | 0x01001000 |

| Rear light | 0x01001001 |

| Stop/Off | 0x00100000 |

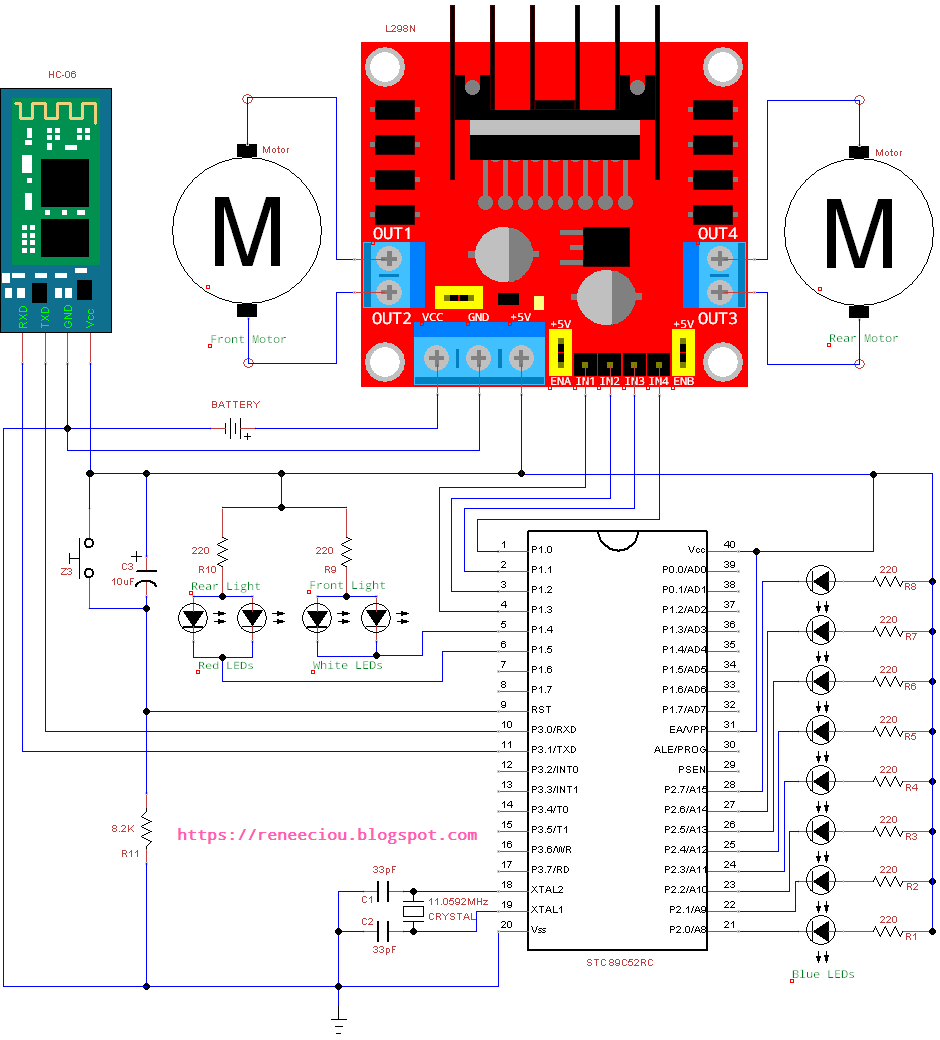

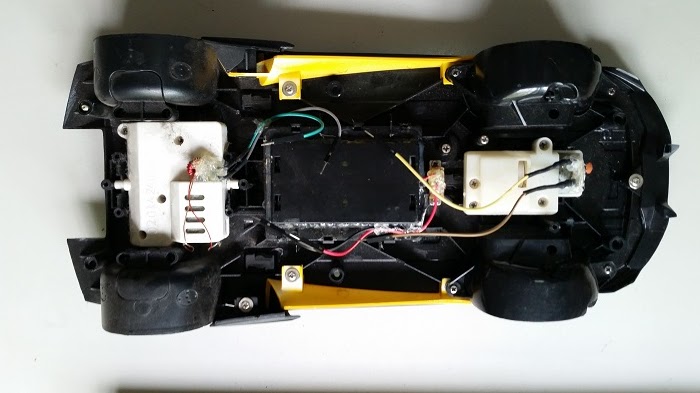

After buying this toy car I have replaced its RF circuit with the 8051 circuit. This toy car has two dc motors at its front and rear side. The front motor is used to control direction (left/right). And the rear motor is used to control the forward and backwards movement. A HC-06 Bluetooth module is used to receive command from android phone. A L298N H-bridge module allows you to control the speed and direction of two DC motors. A STC89C52RC microcontroller is used to control the whole system.

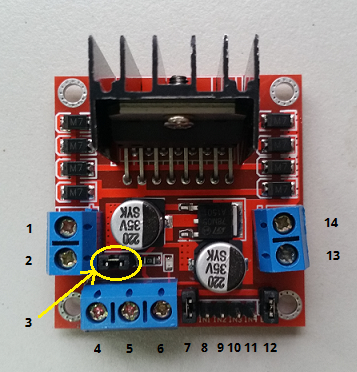

L298N H-bridge module

For more details about this module, please read here. I recommend you read it before you start.

Pin Description

- Front DC motor "+"

- Front DC motor "-"

- 12V jumper - Leave this in place for this tutorial.

- Connect your motor supply voltage here and use between 7 and 12V DC to driver the motors for this tutorial.

- GND

- 5V output - If you're using between 7 and 12V DC to driver the motors and leave 12V jumper in place, the module can also supply your 8051 microcontroller with 5V DC.

- ENA - Front DC motor enable jumper. Leave this in place for this tutorial. If you want to control the speed of the front DC motor you must connect PWM output from your microcontroller to the ENA. For STC89C52RC, there is no PWM output. But you can use timer to implement PWM on 8051 if you want.

- IN1 - Direction of the front DC motor.

- IN2 - Direction of the front DC motor.

- IN3 - Direction of the rear DC motor.

- IN4 - Direction of the rear DC motor.

- ENB - Rear DC motor enable jumper. Leave this in place for this tutorial. If you want to control the speed of the rear DC motor you must connect PWM output from your microcontroller to the ENB. For STC89C52RC, there is no PWM output. But you can use timer to implement PWM on 8051 if you want.

- Rear DC motor "+"

- Rear DC motor "-"

Front motor truth table

| ENB | IN3 | IN4 | Description |

|---|---|---|---|

| 0 | N/A | N/A | Off |

| 1 | 0 | 0 | Stop |

| 1 | 0 | 1 | Anti-clockwise |

| 1 | 1 | 0 | Clockwise |

| 1 | 1 | 1 | Brake |

Rear motor truth table

| ENA | IN1 | IN2 | Description |

|---|---|---|---|

| 0 | N/A | N/A | Off |

| 1 | 0 | 0 | Stop |

| 1 | 0 | 1 | Anti-clockwise |

| 1 | 1 | 0 | Clockwise |

| 1 | 1 | 1 | Brake |

It is important to choose the right voltage for your power supply. Too low will result in reduced performance. Too high will cause damage to the motor. Make sure that the voltage does not exceed the voltage rating of your motors. For my toy car, I use two Panasonic NCR18650B 3.6 Volt 18650 batteries connected in series to supply approximately 7.2V. For your toy car, please choose the right voltage for your power supply. It depends on your motors.

Circuit Diagram

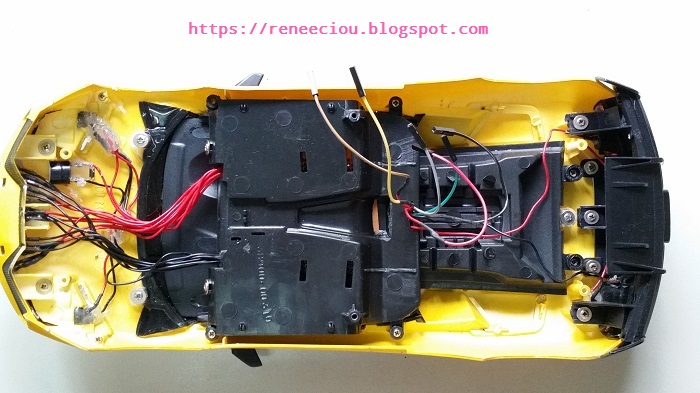

The following toy car is built by myself.

The following code is written in assembly language. You can rewrite it in C language. I think 8051 assembly language is not difficut. Its instruction set is not large so if you are a beginner, you can try to write programs in 8051 assembly language. There will be more understanding of 8051 microcontroller. But if code is more complex and large, and also consider the readability and portability, it is recommended to write code in C language. As for the 8051 development environment, you can refer to here.

Assembly Code

STOP BIT 20H

TURN BIT 21H

R_ON BIT 22H

G_ON BIT 23H

B_ON BIT 24H

B_STP BIT 25H

KP_MV BIT 26H

ORG 00H

AJMP START

ORG 23H ;Serial interrupt vector address

AJMP SERIAL_ROUTINE

ORG 2BH ;Timer2 interrupt vector address

AJMP TIMER2_ROUTINE

START:

ACALL INIT

ACALL INIT_SERIAL

ACALL INIT_TIMER2

LOOP:

ACALL DELAY

JNB B_ON, STOP_BLUE_LED

JB TURN, TURN_AROUND

MOV P2, A

RL A

CJNE A, #01111111B, SET_TURN_RIGHT

SETB TURN

AJMP LOOP

SET_TURN_RIGHT:

AJMP LOOP

TURN_AROUND:

MOV P2, A

RR A

CJNE A, #11111110B, SET_TURN_LEFT

CLR TURN

AJMP LOOP

SET_TURN_LEFT:

AJMP LOOP

STOP_BLUE_LED:

JNB B_STP, RESET_DONE

CLR B_STP

MOV A, #11111110B

CLR TURN

MOV P2, #255

RESET_DONE:

AJMP LOOP

;--------------------

; Delay

;--------------------

DELAY: MOV R6, #100

DLY1: MOV R7, #255

DLY2: DJNZ R7, DLY2

DJNZ R6, DLY1

RET

;--------------------

; Initialize variables

;--------------------

INIT:

MOV SP, #60H

CLR STOP

CLR TURN

CLR R_ON

CLR G_ON

CLR B_ON

CLR B_STP

MOV A, #11111110B

MOV P0, #0

MOV P1, #00110000B

MOV P2, #255

MOV R5, #15

RET

;--------------------

; Initialize serial

;

; TCON Register:

; 7 6 5 4 3 2 1 0

; TF1 TR1 TF0 TR0 IE1 IT1 IE0 IT0

;

; TMOD Register:

; 7 6 5 4 3 2 1 0

; GATE1 C/T1# M11 M01 GATE0 C/T0# M10 M00

;

; SCON Register:

; 7 6 5 4 3 2 1 0

; SM0 SM1 SM2 REN TB8 RB8 TI RI

;--------------------

INIT_SERIAL:

MOV SCON, #50H ;Mode 1: 8-bit UART

MOV TMOD, #20H ;Timer and reload mode

MOV TH1, #0FDH ;Baud rate 9600bps

MOV TL0, #0FDH ;Baud rate 9600bps

SETB TR1 ;Timer1 runs

SETB PS ;High interrupt priority

SETB ES ;Enable serial interrupt

RET

;---------------------------------------------------

; Initialize timer2

;

; T2CON Register:

; 7 6 5 4 3 2 1 0

; TF2 EXF2 RCLK TCLK EXEN2 TR2 C/T2 CP/RL2

;

; 1 second = 11.0592MHZ / 12 = 921600 = 61440 * 15

; TH2 = (65536-61440)/256 = 16 = 10H

; TL2 = (65536-61440)%256 = 0 = 00H

;

; 0.5 second = 30720 * 15

; TH2 = (65536-30720)/256 = 136 = 88H

; TL2 = (65536-30720)%256 = 0 = 00H

;

; 0.25 second = 15360 * 15

; TH2 = (65536-15360)/256 = 196 = C4H

; TL2 = (65536-15360)%256 = 0 = 00H

;

; IE Register:

; 7 6 5 4 3 2 1 0

; EA - ET2 ES ET1 EX1 ET0 EX0

;---------------------------------------------------

INIT_TIMER2:

CLR EXF2 ;Reset flag

CLR TCLK ;Disable baud rate generator

CLR RCLK ;Disable baud rate generator

CLR EXEN2 ;Ignore events on T2EX

MOV TH2, #0C4H

MOV RCAP2H, #0C4H

MOV TL2, #00H

MOV RCAP2L, #00H

CLR CT2 ;Timer mode

CLR CPRL2 ;Reload mode

CLR PT2 ;Low interrupt priority

SETB ET2 ;Enable timer2 interrupt

SETB EA ;Global interrupts enable

SETB TR2 ;Timer2 run

RET

;-----------------------------------

; Timer2 interrupt service routine

;

; This is very important for the toy

; car to stop all actions when the

; bluetooth signal of your toy car

; is out of range, and no command

; is received after (0.25 * 2) second.

;

;-----------------------------------

TIMER2_ROUTINE:

PUSH ACC ;Save ACC register on the stack

DJNZ R5, CONTINUE ;Continue timer if it is less then 1 second

JB KP_MV, NO_CLEAR

CLR P1.0 ;Stop forward

CLR P1.1 ;Stop backward

CLR P1.2 ;Stop right

CLR P1.3 ;Stop left

NO_CLEAR:

CLR KP_MV

MOV R5, #15 ;Recount 0.25 second

CONTINUE:

CLR TF2 ;Reset interrupt flag

POP ACC ;Restore ACC

RETI

;----------------------------------------

; Serial port interrupt service routine

;----------------------------------------

SERIAL_ROUTINE:

PUSH ACC

SETB KP_MV

MOV A, SBUF

JNB A.5, RED_BUTTON

SETB STOP

CLR A.5

RED_BUTTON:

CJNE A, #01000001B, GREEN_BUTTON

JB STOP, STOP_RED_BUTTON

SETB R_ON

LJMP EXIT

STOP_RED_BUTTON:

CLR R_ON

CLR STOP

LJMP EXIT

GREEN_BUTTON:

CJNE A, #01000010B, BLUE_BUTTON

JB STOP, STOP_GREEN_BUTTON

SETB G_ON

SJMP EXIT

STOP_GREEN_BUTTON:

CLR G_ON

CLR STOP

SJMP EXIT

BLUE_BUTTON:

CJNE A, #01000011B, FORWARD

JB STOP, STOP_BLUE_BUTTON

SETB B_ON

SJMP EXIT

STOP_BLUE_BUTTON:

CLR B_ON

CLR STOP

SETB B_STP

SJMP EXIT

FORWARD:

CJNE A, #01000100B, BACKWARD

JB STOP, STOP_FORWARD

SETB P1.0

SJMP EXIT

STOP_FORWARD:

CLR P1.0

CLR STOP

SJMP EXIT

BACKWARD:

CJNE A, #01000101B, RIGHT

JB STOP, STOP_BACKWARD

SETB P1.1

SJMP EXIT

STOP_BACKWARD:

CLR P1.1

CLR STOP

SJMP EXIT

RIGHT:

CJNE A, #01000110B, LEFT

JB STOP, STOP_RIGHT

SETB P1.2

SJMP EXIT

STOP_RIGHT:

CLR P1.2

CLR STOP

SJMP EXIT

LEFT:

CJNE A, #01000111B, CAR_FRONT_LIGHT

JB STOP, STOP_LEFT

SETB P1.3

SJMP EXIT

STOP_LEFT:

CLR P1.3

CLR STOP

SJMP EXIT

CAR_FRONT_LIGHT:

CJNE A, #01001000B, CAR_REAR_LIGHT

JB STOP, STOP_FRONT_LIGHT

CLR P1.4

SJMP EXIT

STOP_FRONT_LIGHT:

SETB P1.4

CLR STOP

SJMP EXIT

CAR_REAR_LIGHT:

CJNE A, #01001001B, EXIT

JB STOP, STOP_REAR_LIGHT

CLR P1.5

SJMP EXIT

STOP_REAR_LIGHT:

SETB P1.5

CLR STOP

EXIT:

CLR RI

POP ACC

RETI

END

Demo

Warning and disclaimer:

If you don't have any basic electronics knowledge, please don't try this one. The author takes no responsibility for any damages caused as a result of this tutorial. Try this one at your own risk.

沒有留言:

不接受新意見。